Specification:

Rectangular Sound Attenuators made of high quality 1 mm thick Galvanized Sheet with 100 to 200 mm thick baffles consisting of 48 Kg/m3 density rockwool lined with RP tissue and perforated sheets and 150 to 200 mm air way gap as standard with V shaped entry and exit. Different specifications can be made to customer requirements based of sound attenuation requirements.

Rectangle Sound Attenuators

Model No. : ARL

DESCRIPTION

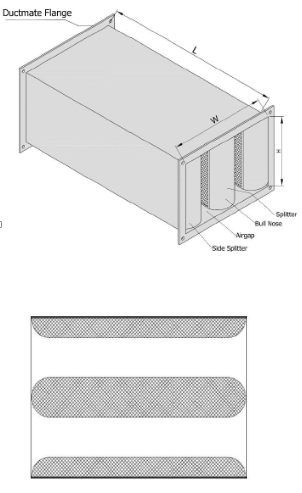

- Aerodynamically designed to ensure maximum insertion loss and minimal pressure drop. Air gap and length of silencer are selected to meet the required NC level.

- Sturdy construction and high noise absorbing capacity to obtain required insertion loss without compromising performance. Manufactured to ensure long and maintenance free service.

- Splitters are made of V shaped entry-exit to minimize self-generated noise and pressure loss and avoid turbulance.

- Full width splitters in the middle and half width side splitters.

- Casing construction with lock formed seams meet SMACNA standards thus proving excellent strength and rigidity. Thoroughly sealed to prevent air leakage.

- Duct mate flange connection (standard) on both ends in compliance with DW144 standards.

- Acoustic infill media is of superior quality non combustible & have fungi resistant characteristics meeting the requirements of EN ISO 1182 and ASTM C665 respectively. It has excellent noise reduction coefficient characteristics with an additional qualification of being biologically inert. Single faced liner with perforated metal is provided to prevent media entering into the air stream.

- Standard available air gaps are 50, 75, 100, 125, 150, 175, 200 and 250 mm.

- Fibre glass insulation available as option.

- Tested and certified by Intertek USA (NVLAP accredited laboratories) in accordance with ASTM standard E477-06a, entitled “standard method of testing duct line material and prefabricated silencers for acoustical and airflow performance”.

PRODUCT ORDER CHECKLIST

To Design:

- Required Room Sound Criteria

- Airflow data for each silencer

- Duct Size and maximum length available

- Noise levels of air handling units

To Manufacture:

- Size: W x H x L

- Material: GI / Aluminium

- Insulation Media and Density

- Baffle Thickness

- Airway Gap

INSTALLATION GUIDE

- Allow at least 2-5 duct diameters in the upstream and downstream for better silencer efficiency.

- Do not expose the silencer to dirt or excess humidity during installation or storage.

- The HVAC system should be designed meticulously for proper dehumidification and air-filtration to prevent microbial growth within the silencer and the duct system.

- It is recommended to install the silencer after the volume control damper to prevent regenerated noise.