Specification:

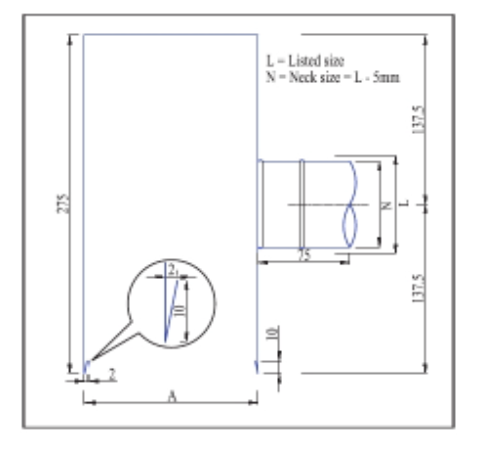

Plenum Boxes for HVAC Systems made of high quality galvanized sheet of required gauge and 50mm spigot as standard. Insulation of required thickness and density as well as butterfly damper are available as options.

Plenum

DESCRIPTION

- Fabricated from 24, 22 or 20 gauge high quality glavanised steel sheet.

- Circular spigots of required diameter and standard length of 50mm as standard can be fixed to the plenum box. Square, rectangle and oval shape spigots are available on request.

- Plenum boxes with side inlet are standard. Other positions are available as per the site conditions to suit client specifications.

- Plenum Boxes for HVAC Systems of length upto two meters can be manufactured with single spigot. For more than 2 meters plenum boxes will be arranged with multiple spigots.

- Volume control butterfly dampers can be fixed to the spigots on request.

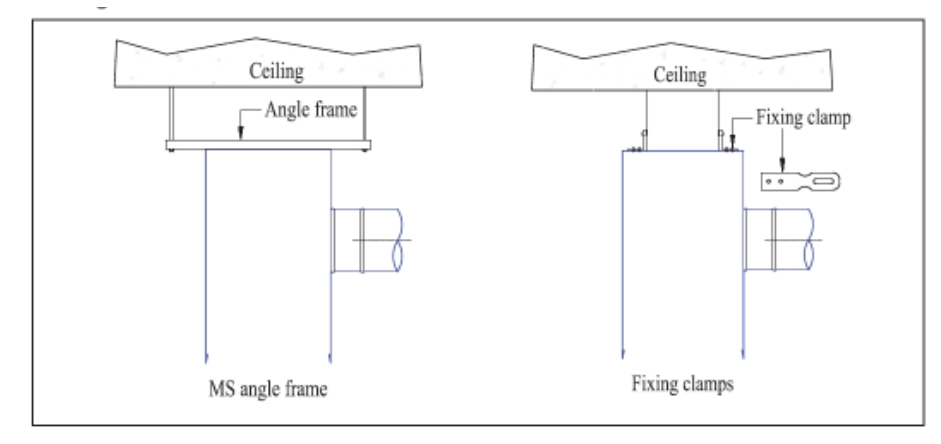

- Fixing brackets are provided at all four corners on the top side by default for hanging the plenum from ceiling.

- Large size plenums can be specially manufactured on request.

PRODUCT ORDER CHECKLIST

| MODEL | FLANGE | INSULATION OPTIONS | ACCESSORIES | ||

|---|---|---|---|---|---|

| MATERIAL | THICKNESS | DENSITY | |||

| APB | 25 mm | Fibre Glass | 25 | 24 | Butterfly |

| 50 mm | Nitrile Rubber | 50 | 48 | Damper | |

FIXING DETAILS

Plenum Boxes for HVAC Systems - Faq

What is a Plenum Boxes for HVAC Systems, and What Does It Do?

In Plenum Boxes for HVAC Systems, a plenum is an air distribution chamber that houses the heated or cooled air before it circulates through the ductwork to different rooms. There are generally two types: the supply plenum, which is attached to the furnace or air handler, and the return plenum, which connects to the return duct. The supply plenum allows air to flow from the system into the ducts, while the return plenum draws room air back into the system for reconditioning. Plenums play a crucial role in maintaining balanced airflow and ensuring that the HVAC system can efficiently deliver temperature-controlled air to all areas, optimizing comfort and system performance.

What Are the Differences Between a Supply and a Return Plenum?

The supply and return plenums serve opposite functions within the Plenum Boxes for HVAC Systems. A supply plenum is responsible for distributing conditioned air from the HVAC unit into the ductwork and ultimately into rooms. In contrast, a return plenum collects air from each room through return ducts, delivering it back to the Plenum Boxes for HVAC Systems for reconditioning. This cycle maintains a balanced air pressure and efficient circulation throughout the building. Supply plenums are usually directly connected to the furnace or air handler, while return plenums are attached to return ducts. Both types are essential for ensuring even, consistent airflow within the HVAC system.

Why is the Proper Sizing of a Plenum Important in HVAC Systems?

Proper plenum sizing is critical because it affects the airflow efficiency and temperature control within an HVAC system. If a plenum is too small, it may restrict airflow, leading to uneven temperature distribution, increased system strain, and potential energy inefficiency. Conversely, an oversized plenum may cause air pressure imbalances, resulting in insufficient airflow to certain areas. Correct sizing ensures that the HVAC system can circulate air optimally, maintain balanced pressures, and operate efficiently, which ultimately extends the life of the system and contributes to better indoor air quality and comfort.

What Materials are Commonly Used to Construct Plenums?

Plenums are typically constructed from materials such as galvanized steel, aluminum, or fiberglass, each chosen based on durability and the specific HVAC application. Galvanized steel is the most common choice due to its strength, corrosion resistance, and ability to withstand various temperatures. Aluminum is lightweight and provides good corrosion resistance, suitable for systems where weight is a concern. Fiberglass plenums, often pre-insulated, are beneficial for noise reduction and temperature insulation. Some systems also use flexible duct material for plenums in smaller applications, though it’s less common. The choice of material impacts the system’s durability, noise level, and energy efficiency.

How Do Plenums Impact Indoor Air Quality in an HVAC System?

Plenums can significantly impact indoor air quality (IAQ) as they are the primary channels for distributing air throughout a building. Dust, debris, or contaminants that collect in a plenum can be circulated into living spaces if not regularly cleaned. Using air filters within the HVAC system helps to reduce this risk by trapping pollutants before they enter the plenum. Additionally, properly sealed and insulated plenums prevent the infiltration of outdoor air contaminants or pollutants from other building spaces, such as attics or basements. Regular inspection and maintenance of the plenum are essential to maintaining high indoor air quality.

Can Plenum Insulation Improve Plenum Boxes for HVAC Systems Efficiency?

Yes, insulating the plenum can enhance Plenum Boxes for HVAC Systems efficiency by minimizing heat gain or loss as air passes through it. Without insulation, conditioned air can lose energy, particularly in unconditioned spaces such as attics or basements, where temperature differences are more significant. Insulated plenums reduce these losses, allowing air to maintain its temperature as it flows through the ductwork. This efficiency leads to less energy consumption, lower utility bills, and more consistent indoor temperatures. Insulated plenums also help reduce noise levels by dampening sound vibrations within the ductwork, contributing to a quieter system operation.

How Often Should Plenum Boxes for HVAC Systems be Cleaned and Maintained?

Plenums should be inspected and, if necessary, cleaned during regular HVAC maintenance, typically once or twice a year. Dust, dirt, and other contaminants can accumulate within the plenum, especially in the return plenum, potentially impacting air quality and system efficiency. Routine inspections can detect any blockages, mold growth, or debris buildup early, ensuring they don’t affect airflow. During maintenance, technicians will check for leaks, loose connections, and insulation integrity to maintain optimal performance. Regular plenum cleaning and maintenance extend the HVAC system’s life and contribute to better indoor air quality and energy efficiency.

What are Common Issues that Affect Plenum Boxes for HVAC Systems Performance?

Several issues can impact plenum performance, including leaks, blockages, insulation degradation, and improper sizing. Leaks in the plenum can reduce system efficiency by allowing conditioned air to escape, increasing energy costs. Blockages caused by debris or dust buildup can restrict airflow, making it harder for the system to maintain desired temperatures. Degraded insulation allows for heat gain or loss, affecting temperature control and efficiency. Additionally, an incorrectly sized plenum can lead to air pressure imbalances and uneven distribution, impacting comfort and potentially stressing the HVAC system. Regular maintenance helps identify and address these issues early.

How Do Plenum Boxes for HVAC Systems Help with Noise Reduction in HVAC Systems?

Plenums help reduce noise in HVAC systems by allowing the air to distribute more evenly before entering the ductwork, preventing sudden pressure changes that can cause noise. Insulated plenums are particularly effective in noise reduction, as insulation dampens sound vibrations caused by moving air. By maintaining balanced air pressure and minimizing turbulence, plenums contribute to a quieter HVAC operation, especially in high-velocity systems. Using insulated plenums in commercial spaces can enhance comfort by limiting noise levels, creating a quieter environment while maintaining efficient air distribution and system functionality.

Can Plenum Boxes for HVAC Systems be Retrofitted or Modified in Existing HVAC Systems?

Yes, plenums can be retrofitted or modified to improve airflow and system efficiency in existing HVAC systems. Retrofitting may involve resizing, adding insulation, or sealing leaks to enhance performance. In older systems, upgrades like adding a return Plenum Boxes for HVAC Systems or increasing insulation can significantly impact energy efficiency and comfort. Professional HVAC technicians can evaluate the current system’s design and recommend modifications that improve airflow and balance. Retrofits are an effective solution for extending the lifespan of an HVAC system without the cost of full replacement, ensuring that the plenum and overall system operate at their best.